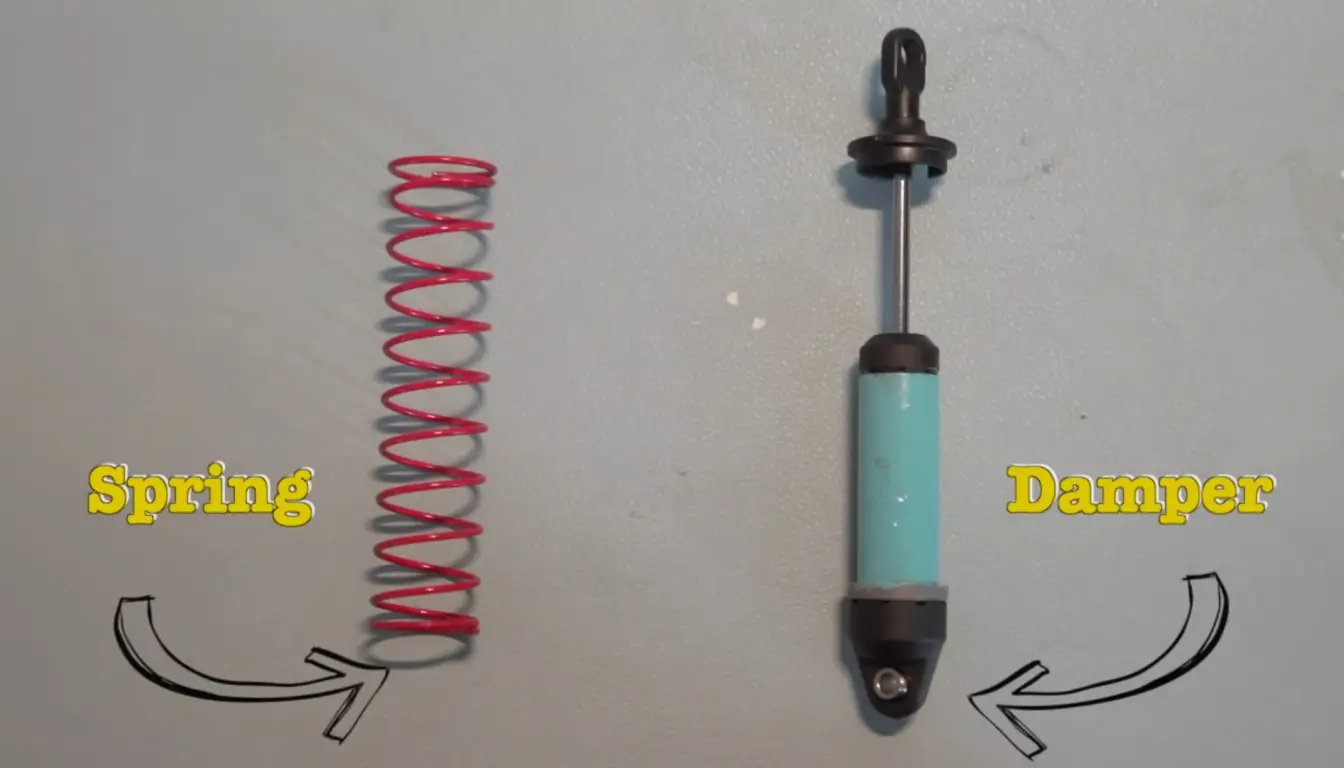

Mountain Bike suspensions work by using a system of front and rear suspensions. Both sides of the suspension contain two crucial elements a spring and a damper. These are also more commonly called shock absorbers.

The suspension allows the wheels to move up and down to cushion tiny bumps while maintaining tire contact for smooth handling. It also aids in the absorption of large shocks while landing jumps by the rider and the bike.

This article is for anyone who is eager to know how bike suspensions work and has other questions, which will all be answered here.

How do Bike Suspensions work?

Suspensions are important to control and handle a vehicle more efficiently. They are used to provide more friction and contact with the road and cushion any bumps.

In terms of bike suspensions, they mainly operate using a configuration of front and back suspensions. They are equipped with components called the spring and damper, which are more commonly known as shock absorbers.

Suspensions absorb impact forces and allow for smoother and safe riding.

What are Springers?

Because of the spring, the suspension is able to go as the wheel comes into contact with a bump and then swiftly moves back down once the wheel has passed over the hump. Either a cylinder filled with compressed air or a steel coil can make up the spring. The majority of the springs that we are familiar with are made of steel

In either scenario, the amount that the spring is compressed determines how much effort is required to further squeeze it, which is precisely what is required for a suspension system on a mountain bike. When you land a difficult jump, you do not want the spring to compress all the way to its minimum height.

The damper is part of the shock absorber on a mountain bike. As the piston goes up and down, it forces oil through a series of tiny holes into the system.

What are Dampers?

The component of the suspension that is responsible for absorbing energy and preventing the springs from bouncing uncontrollably is the damper. If the suspension consisted of nothing more than a spring, the vehicle would ride over bumps only once before beginning to repeatedly rise and fall.

When the springs in a suspension system are pressured by a bump, there needs to be a means for the system to release the energy that has been stored in the springs.

Oil-filled dampers are by far the most prevalent variety of damper. This particular sort of damper can be found in the suspensions of both automobiles and bicycles. When the spring is compressed, it causes a piston inside the shock absorber to move, which forces oil to travel through a narrow opening.

It takes a certain amount of energy to compel the fluid to go through the opening, and the oil absorbs this energy and converts it into heat. The faster you attempt to compress the shock absorber, the more energy is dissipated by the oil-filled dampers and the more resistance they give to motion. This is a cool feature of oil-filled dampers.

When the suspension system compresses at a faster rate, a larger amount of liquid has to pass through the orifice; as a result, the orifice needs to be subjected to a higher pressure in order to facilitate the flow of fluid.

The higher flow accomplishes two goals at once: first, it makes the suspension more rigid (due to the fact that the compression opposes the movement of the suspension system), and second, it causes a greater amount of energy to be lost.

Finding the optimal spring rate (which refers to the spring’s degree of stiffness) and the damping balance is an important aspect of the process of designing an effective shock absorber. As a result of this, numerous shock absorbers feature adjustable damping and spring rates.

Some compressed-air springs have the capability of having the air pressure raised or lowered in order to achieve the desired tension.

Front Suspension System

For most vehicles, the suspension fork is the most common kind of front suspension. It operates in a manner analogous to the front suspension of a motorcycle.

The component of the fork that sits at the bottom and is responsible for holding the wheel is designed to slide over the tubing that serves to link its fork to the chassis. A shock much like the one depicted in the diagram that we just looked at is housed inside every tube on the fork.

The spring is compressed, and fluid is forced through the orifice when the fork goes upward (as it does when the bike hits an obstacle), which causes the piston to move.

Rear Suspension System

The number of rear suspension configurations is comparable to the number of bicycle manufacturers. The majority of them employ a shock absorber, typically equipped with a bigger coil spring. The frame and linkage are the primary areas of customization on bicycles.

Because the linkage provides the wheel with force applied over the spring, larger springs are typically required for the rear suspensions. The pressure on the shock absorber is three times that of the tire. Both front shocks take half the force acting on the tire.

Improvements in frame design have followed advances in suspension technology.

Conclusion

Without suspensions, riding a bike would be much riskier and more problematic. Suspensions are what allow for a smoother and safer ride.

A full suspension system, like rear and front suspension, includes, is the latest technology and also helps absorb obstacle bumps much more efficiently.

I hope this article answers all your questions.

I am Ryan Ford, a mountain biking enthusiast who loves to explore the outdoors. I also like to go on adventures with friends and anything else that involves being outside. I love my bike because it gets me out of the house and gives me an opportunity to enjoy nature.